Experience the future now

SIPs are the future of affordable housing

Build your new home faster, easier and smarter.

Structural Insulated Panels (SIPs)

Simple Innovative Prefab Structure

Applications (Flexible and Adaptable )

Structural Insulated Panels (SIPs) are an advanced and inventive method of construction that are used in a wide range of residential, commercial and educational project applications, providing ecologically friendly and energy efficient buildings.

SIP panels can be used to quickly erect a combination of floors, internal and external walls and roofs. All of this without the need for a traditional timber frame. In fact SIPs are stronger than stick build framing, but weigh significantly less.

SIPs are used to build new homes, tiny cabins, extensions to existing homes, such as a second floor. Or for commercial applications they can be used to build schools, office space, low level shops, hospital, or a large open space such as a warehouse or factory.

SIP structures can also be stacked on top of each using a load bearing structural system up to a height of 18 metres. However large or tall SIPs structures may require a secondary framing system of steel or timber.

Competitive Edge

How are EzySIPs different than competition

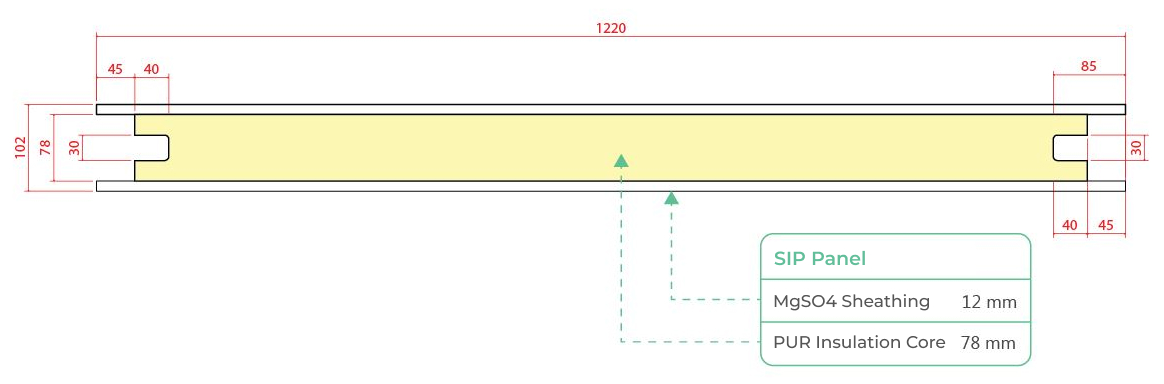

Whilst the majority of SIPs available in the market have OSB (Orientated Strand Board) as the skin and EPS (Expanded Polystyrene) as the core, we’ve chosen to manufacture and supply only the best possible option. After extensive research we have opted for MgSO4 for the skins and PU for the core. Both materials are substantially superior to OSB SIPs with EPS core in terms of structural integrity, sound and thermal insulation, plus longevity.

EzySips Panels with MgSO4 Skins and PU core are extremely strong, durable, energy efficient and cost effective.

EzySips Panels with MgSO4 Skins and PU core are extremely strong, durable, energy efficient and cost effective. MgSO4 board has a 2 hour fire rating and is non corrosive, whilst PU also has a high fire resistance and does not hold flame. Both materials are exceptionally water resistant.

Unique Manufacturing process

How are our EzySIPs made

EzySip panels are made with MgSO4 (Magnesium Sulphate Board) as the skin with a PU core (Polyurethane Insulation Foam) The 2 skins of MgSO4 board are placed in a specialised jig, then the liquid form PU is injected under pressure into the space between the two MgSO4 boards. This guarantees the strongest possible bond between the skins and the core, ensuring maximum strength.

Technical Details

Eco Friendly, Structurally Robust, Panelised Precision

MgSO4 board is made from Magnesium which is a common element and is so safe for humans that it’s used as a mineral supplement for medical purposes, so it has many health benefits. MgSO4 is strong, durable, high impact resistant and waterproof, ensuring it’s also an optimal building material for flood prone or cyclone areas.

PU or PUR is a polyurethane that is completely inert and harmless to humans. It also has superior strength, thermal resistance and dimensional stability over other materials.

Benefits of using MgSO4 Skins with PU Core for SIP Panels

Building a better future, driven by innovation

Structural Integrity - Extremely Strong, Durable and Impact Resistant

Fireproof - Unlike any other SIPS they do not hold a flame

Termite Resistant - No nutrients to feed insects or mould

Water Resistant - Do not swell, warp or delaminate, plus non corrosive

Thermal Rating - Exceptional R rating, almost double other SIPs

Sound Rating - Have superior acoustic values over OSB or Fibre Cement

Eco Friendly - No off gassing and virtually VOC free

Sustainable - 50% lower carbon footprint and 100% recyclable

Non Toxic - Zero Heavy Metals, no Organic Solvents, Zero Asbestos

Rapid affordable dwellings

"Welcome to EZY SIPs, where we are revolutionising the construction industry by delivering innovative and affordable homes at unprecedented speed."

EZY SIPs are crafted with precision and designed for flexibility and sustainability. SIP panels redefine building techniques, energy efficiency, durability, and design flexibility.

Whether you're an architect, builder, or a homeowner, it's time to embrace the future and experience the unparalleled benefits of leading edge construction forms using Structural Insulated Panels (SIP).